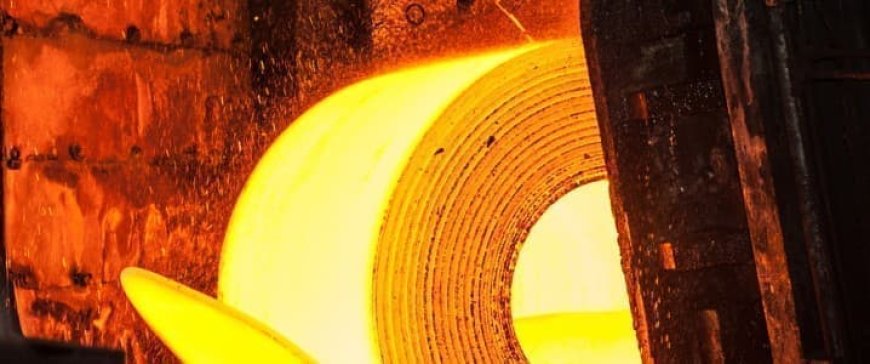

British Steel Plans to Build Electric Arc Furnace at Scunthorpe Site

Via Metal Miner British Steel recently secured permission from the local authorities to build an electric arc furnace at its Scunthorpe site in Lincolnshire. In an April 30 announcement to steel news outlets, the London-headquartered company stated that the North Lincolnshire council approved its application to build a new EAF at Scunthorpe following a consultation. Officials at British Steel did not indicate a timeline for the new EAF to come on stream. However, a spokesman told MetalMiner that the furnace will have a capacity of 130 metric tons…

- British Steel plans to construct a 130 metric-ton capacity electric arc furnace (EAF) at its Scunthorpe site following local authority approval.

- The new EAF is part of a £1.25 billion decarbonization initiative, replacing traditional blast furnaces with more environmentally-friendly technology.

- Additional EAF projects are underway, including a site at Teesside, with ongoing discussions for government funding and potential impacts on jobs at other sites.

Via Metal Miner

British Steel recently secured permission from the local authorities to build an electric arc furnace at its Scunthorpe site in Lincolnshire. In an April 30 announcement to steel news outlets, the London-headquartered company stated that the North Lincolnshire council approved its application to build a new EAF at Scunthorpe following a consultation.

Officials at British Steel did not indicate a timeline for the new EAF to come on stream. However, a spokesman told MetalMiner that the furnace will have a capacity of 130 metric tons for each charge. “Significant preparation works, including environmental and technical studies, and equipment selection, are underway,” the spokesman added in an e-mail.

Scunthorpe currently has four blast furnaces for steel manufacturing: Mary, Bess, Anne, and Victoria. These can produce up to 4.7 million metric tons per year of pig iron. The site can also produce 4.5 million tons of crude steel annually via three 330-metric ton basic oxygen furnaces, which it casts billets and slabs for rolling. Meanwhile, rolling mills on site can produce wire rod, sections, and heavy plates.

On April 2, British Steel announced that it also received permission from local authorities to build an EAF at its Teesside site in northeastern England. The planned EAFs are part of a £1.25 billion ($1.56 billion) decarbonization plant that British Steel announced in November, which would see the company replace its blast furnaces with the newer, more environmentally-friendly technology.

Talks are also continuing with the UK government on funding for the project, the spokesman told MetalMiner. Meanwhile, the Welsh First Minister, Vaughan Gething, was due to depart for India in early May. Gething hoped to reach out to Tata Steel officials and make the case for not blowing down the blast furnaces at the Port Talbot. Tata announced its plans to replace those furnaces as well as their basic oxygen furnaces with electric arc furnace technology in January of 2024

Tata’s Modernization Plan to Cut 40% at Port Talbot

The new equipment would cut crude steel production capacity at the integrated flats producer by 40% to 3 million metric tons per year from its current nameplate capacity of 5 million metric tons. About 2,800 jobs face redundancy at Port Talbot and at the Llanwern cold rolling plant as a result of the new hot end.

In April, unions associated with Port Talbot voted to strike over Tata’s plans and the Indian group’s rejection of their proposal to keep one blast furnace on stream while the EAF remained under construction.